Collection: Oven Cleaning and Degreasers

Professional oven cleaning products designed for effective grease and carbon removal from domestic and commercial ovens. Featuring trusted brands including Selden trigger sprays, HG degreasers and Kodex combi oven detergents. Essential solutions for catering establishments, food service operations and cleaning contractors requiring reliable results.

Oven Cleaning Product information

Oven cleaning represents one of the most challenging aspects of kitchen maintenance, requiring specialised products designed to tackle baked-on grease, carbonised food residues, and stubborn deposits that accumulate through regular cooking operations.

At ClickCleaning, we provide professional-grade oven cleaning solutions from trusted manufacturers including Selden, HG, and Clover Chemicals, formulated to deliver exceptional results across diverse applications from light domestic maintenance to heavy-duty commercial kitchen environments. Our comprehensive range includes powerful trigger spray cleaners for manual application, concentrated degreasers for intensive deep-cleaning operations, and specialised combi oven detergents designed for automated cleaning systems.

The complexity of oven cleaning stems from the combination of high temperatures, grease accumulation, and food residues that create multiple contamination layers requiring different chemical approaches. Effective oven cleaning products must penetrate these deposits, break down the molecular bonds created by heat polymerisation, and enable easy removal without damaging oven surfaces or leaving harmful residues that could affect food safety.

Our Selden oven cleaners feature ready-to-use trigger spray formulations that cling effectively to vertical surfaces without producing excessive fumes,

making them ideal for both professional and domestic applications. These products are designed to work efficiently on warm surfaces whilst providing

flexible contact times from one minute to several hours depending on soiling severity, offering adaptability for different cleaning schedules and contamination levels.

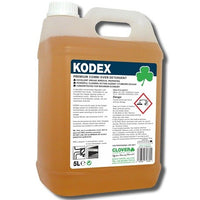

For commercial applications requiring automated cleaning solutions, our Kodex combi oven detergents are specifically formulated for use through integral oven cleaning systems. These concentrated products are designed for automatic dosing during the oven's own cleaning programme, providing superb economy whilst effectively removing grease and carbonised deposits in both atmospheric and non-atmospheric oven types.

The HG range offers specialist solutions for ovens, grills, and barbecues, featuring formulations that work quickly and effectively on baked-on dirt and

grease. These products are designed for ease of use with simple application procedures whilst delivering professional-grade cleaning performance suitable for both commercial and domestic environments.

Safety considerations remain paramount in oven cleaning operations, as these products necessarily contain powerful active ingredients capable of breaking down stubborn deposits. All our oven cleaners are formulated to minimise user exposure risks whilst maintaining exceptional cleaning effectiveness, though proper protective equipment and ventilation remain essential for safe application.

Compatibility with different oven types and surfaces ensures our range accommodates conventional ovens, combination ovens, grills, and associated equipment such as racks and trays. The products are formulated to clean effectively without causing damage to oven interiors, seals, or heating elements when used according to manufacturer instructions.

Economic considerations include both the direct cost per application and the labour savings achieved through more effective cleaning processes. Professional-grade oven cleaners typically reduce cleaning time and effort significantly compared to basic alternatives, whilst delivering superior results that maintain equipment performance and extend service life.

Whether you're managing a busy commercial kitchen, operating catering facilities, maintaining food service equipment, or addressing domestic oven

cleaning requirements, ClickCleaning offers professional-grade solutions that combine proven effectiveness with practical application methods to ensure

optimal results across all oven cleaning applications.

Please contact us if you have any questions about our range we can assist with.

Oven Cleaning FAQs

What's the difference between ready-to-use and concentrated oven cleaners?

Ready-to-use oven cleaners like our Selden trigger sprays offer immediate application convenience without dilution requirements, making them ideal for smaller facilities or occasional deep-cleaning tasks. These products are pre-diluted to optimal strength for direct application, providing consistent results without measuring or mixing procedures. They're particularly suitable for domestic applications and smaller commercial kitchens where simplicity and reliability are priorities. Concentrated oven cleaners, such as our Kodex combi oven detergents, offer superior economy for high-volume applications through precise dilution ratios typically ranging from 0.5-2%. These products are designed for automated dosing systems that ensure consistent dilution and application, making them ideal for busy commercial kitchens with regular cleaning schedules. Concentrated products generally provide lower cost per application whilst requiring compatible dosing equipment and proper handling procedures. The choice depends on your application volume, equipment availability, and operational preferences—ready-to-use products offer simplicity and immediate results, whilst concentrates provide economy and integration with automated cleaning systems for larger operations.

How do I safely use oven cleaning products?

Safe oven cleaner use requires proper preparation, protective equipment, and application procedures to prevent injury and ensure effective results. Always wear rubber gloves as oven cleaners contain strong alkaline chemicals that can cause skin irritation or burns. Ensure adequate ventilation in the work area to prevent inhalation of vapours, and consider respiratory protection for prolonged exposure or confined spaces. Remove all food items and accessories from the oven before cleaning, and allow the oven to cool sufficiently for safe access whilst maintaining warmth for optimal product performance. Apply products evenly using appropriate tools such as brushes or cloths, avoiding contact with electrical components, seals, or surfaces not specified by the manufacturer. Never mix different cleaning products as this can create dangerous chemical reactions. Always read and follow manufacturer instructions regarding contact times, dilution ratios, and application methods specific to your chosen product. After cleaning, rinse surfaces thoroughly with clean water to remove all chemical residues that could affect food safety or cause damage during subsequent heating cycles. Store products securely away from children and food items, and dispose of empty containers according to local environmental regulations.

Can I use the same oven cleaner for different types of ovens?

Most general-purpose oven cleaners are suitable for conventional domestic and standard commercial ovens, but specific oven types may require specialised products for optimal performance and safety. Our Selden trigger spray cleaners work effectively across most conventional ovens, grills, and cookers, providing versatility for facilities with mixed equipment. However, combination ovens with integral cleaning systems require specialised products like our Kodex detergents that are formulated specifically for automated dosing and compatible with the oven's cleaning programme. Self-cleaning ovens typically don't require chemical cleaners during their high-temperature cleaning cycles, though manual cleaning products may be needed for routine maintenance between self-cleaning operations. Convection ovens, steam ovens, and other specialist equipment may have specific material compatibility requirements that affect product selection. Always verify compatibility with your oven manufacturer's recommendations, particularly for warranty considerations and surface

materials. Some ovens feature coatings or finishes that require gentle formulations, whilst others can tolerate more aggressive cleaning products. For facilities with multiple oven types, consider maintaining different products suited to each application rather than relying on a single universal solution that may compromise performance or safety on specific equipment types.

How often should commercial ovens be deep cleaned?

Commercial oven deep-cleaning frequency depends on usage intensity, food types, and operational requirements, but most busy kitchens benefit from weekly deep-cleaning supplemented by daily maintenance cleaning. High-volume operations preparing greasy foods may require deep-cleaning every 3-5 days to maintain performance and prevent excessive buildup that compromises efficiency or creates fire hazards. Combination ovens with automated cleaning systems can often extend intervals to 7-14 days when daily rinse cycles are maintained, as the integrated cleaning removes most deposits before they become problematic. Visual inspection provides the best guide—when grease deposits, carbonised residues, or odours become noticeable, deep-cleaning is overdue regardless of scheduled intervals. Food safety regulations often mandate specific cleaning frequencies for commercial kitchens, so verify local requirements that may supersede general recommendations. Consider operational factors such as menu changes, seasonal variations, and equipment age that affect soil accumulation rates. Preventive cleaning schedules typically prove more cost-effective than reactive approaches, as severe buildup requires more aggressive chemicals, longer contact times, and increased labour investment. Monitor oven performance indicators such as heating efficiency, temperature uniformity, and cooking times that may signal cleaning needs before visual inspection reveals problems.

What's the best way to clean oven racks and removable parts?

Oven racks and removable components often require different cleaning approaches compared to fixed oven interiors due to their portability and material characteristics. For heavily soiled racks, soaking in warm water with appropriate degreasing agents provides effective results—our oven cleaning products can be diluted for soaking applications where manufacturer instructions permit. Consider using deep sinks or specially designated cleaning areas that accommodate full rack dimensions without damage to surrounding surfaces. Mechanical action through brushing or scouring helps remove stubborn deposits, but verify material compatibility to prevent damage to protective coatings or finishes. Some racks benefit from overnight soaking for severe buildup, whilst others may require multiple treatment cycles for complete restoration. Dishwasher cleaning may be appropriate for some removable parts, though verify temperature and detergent compatibility before attempting. For stainless steel components, avoid chloride-based cleaners that could cause pitting or corrosion damage. After cleaning, ensure complete rinsing to remove all chemical residues that could transfer to food during subsequent use. Proper drying prevents water spots and potential corrosion, particularly important for components stored outside the oven environment. Some facilities find dedicated rack cleaning equipment worthwhile for high-volume operations, whilst others prefer manual cleaning methods that provide greater control over valuable equipment components.

Why do some oven cleaners work better on warm surfaces?

Oven cleaner effectiveness improves significantly on warm surfaces due to chemical reaction principles and physical properties that enhance cleaning performance. Heat accelerates chemical reactions, allowing alkaline cleaning agents to break down grease and carbonised deposits more rapidly and completely than on cold surfaces. Warm grease becomes more fluid, enabling better penetration by cleaning solutions and easier removal during the cleaning process. The elevated temperature also improves the solubility of many soil types, particularly proteins and carbohydrates that have been altered by cooking heat. Additionally, warm surfaces prevent rapid cooling of applied cleaning products, maintaining optimal reaction temperatures throughout the contact period. However, surfaces should be warm rather than hot—excessively high temperatures can cause rapid evaporation of cleaning solutions, reducing contact time and effectiveness whilst potentially creating safety hazards from chemical vapours. The optimal temperature range typically falls between 40-60°C, warm enough to enhance chemical activity without creating safety concerns or product instability. For cold cleaning applications, extended contact times compensate for reduced chemical activity—our Selden oven cleaner

instructions specify up to six times longer contact when cleaning cold versus warm surfaces. This flexibility allows cleaning during equipment downtime whilst maintaining effectiveness through adjusted procedures rather than

compromised results.

Are there eco-friendly oven cleaning options available?

Environmental considerations in oven cleaning involve balancing cleaning effectiveness with ecological impact, worker safety, and sustainable practices. Many modern oven cleaners incorporate biodegradable surfactants and reduced volatile organic compounds compared to traditional formulations, offering improved environmental profiles whilst maintaining professional cleaning performance. However, the nature of oven soiling—particularly carbonised deposits and polymerised grease—often requires alkaline chemistry that achieves effective results through powerful active ingredients. Some facilities adopt integrated approaches combining effective chemical cleaning with operational practices that reduce environmental impact, such as proper dilution control, waste stream management, and container recycling programmes. Concentrated products like our Kodex range inherently provide environmental benefits through reduced packaging, transportation impacts, and storage requirements per unit of cleaning accomplished. Preventive maintenance cleaning schedules can reduce the need for intensive chemical treatments by addressing deposits before they require aggressive removal methods. Consider total environmental impact including energy efficiency of cleaned equipment, food safety maintenance, and operational longevity that well-maintained ovens provide. For facilities with specific environmental requirements, we can recommend products with enhanced biodegradability or reduced environmental impact profiles, though effectiveness verification remains important for maintaining operational standards and regulatory compliance in commercial food service environments.

How do I choose between manual and automated oven cleaning systems?

The choice between manual and automated oven cleaning depends on operational factors including oven type, cleaning frequency, labour availability, and cost considerations. Manual cleaning using trigger sprays and similar products offers flexibility for varied cleaning schedules, different soil levels, and mixed equipment types within a facility. This approach requires minimal equipment investment beyond the cleaning products themselves and provides complete operator control over application procedures and contact times. Manual methods suit smaller operations, facilities with diverse equipment, or situations where cleaning schedules vary significantly based on operational demands. Automated cleaning systems, typically found in combination ovens with integral cleaning programmes, offer labour savings and consistency benefits for high-volume operations with regular cleaning schedules. These systems ensure precise chemical dosing, optimal contact times, and complete rinsing cycles without operator variability that can affect results. Automated systems require compatible concentrated products like our Kodex detergents and proper installation of chemical feed systems, but they eliminate labour during actual cleaning cycles and ensure consistent results regardless of operator experience. Cost analysis should include chemical costs, labour requirements, equipment investment, and opportunity costs of equipment downtime during cleaning. Many busy commercial kitchens find automated systems cost-effective through labour savings and improved scheduling flexibility, whilst smaller operations may prefer the lower initial investment and operational flexibility of manual cleaning approaches.

What should I do if oven cleaner doesn't remove all the buildup?

Persistent oven deposits after initial cleaning typically indicate either insufficient contact time, inadequate product strength, or deposits that require mechanical assistance for complete removal. First, verify that you've followed manufacturer instructions regarding contact times, surface temperature, and application procedures, as these factors significantly affect cleaning performance. For stubborn deposits, consider repeating the cleaning process with extended contact time—our Selden oven cleaner can be left for up to overnight contact for severe soiling situations. Ensure the surface remains warm during treatment, as cold surfaces dramatically reduce chemical effectiveness. Mechanical assistance through appropriate brushes, scourers, or scrapers may be necessary for heavily carbonised deposits, though exercise caution to avoid damaging oven surfaces or heating elements. Some deposits may require multiple treatment cycles rather than a single intensive application, particularly in ovens that haven't been properly maintained over extended periods. Consider whether a different product formulation might be more appropriate for the specific soil type or severity you're encountering. For extremely stubborn cases, professional oven cleaning services may be worthwhile, particularly for valuable equipment where damage risks from aggressive treatment could exceed service costs. Prevention through regular maintenance cleaning prevents severe buildup that becomes increasingly difficult to remove, making consistent cleaning schedules more cost-effective than crisis intervention approaches that may require specialised products or professional services.

Can oven cleaning products damage oven surfaces or components?

Quality oven cleaning products are formulated to clean effectively whilst minimising damage risks to properly designed oven surfaces, but improper use or incompatible applications can cause problems. Most conventional oven interiors are designed to withstand alkaline cleaning products, but sensitive components such as heating elements, electronic controls, door seals, and decorative finishes require careful attention during application. Always avoid direct contact between cleaning products and electrical components, sensors, or control systems that could suffer damage from chemical exposure or moisture ingress. Some oven finishes, particularly older enamels or specialty coatings, may be sensitive to aggressive cleaners or extended contact times. Test products on inconspicuous areas before full application if you're uncertain about compatibility. Aluminium surfaces are particularly sensitive to alkaline cleaners and may suffer permanent damage from inappropriate product selection—our product specifications clearly identify materials that should be avoided. Proper rinsing after cleaning is essential to prevent chemical residues from causing ongoing damage during subsequent heating cycles. Door seals and gaskets may require gentler treatment than main oven chambers, as these components often use materials that are less chemically resistant than oven interiors. When in doubt, consult oven manufacturer recommendations or contact us for guidance on product selection for specific equipment types, as preventing damage is far more cost-effective than dealing with repair or replacement consequences from inappropriate cleaning procedures.

How should oven cleaning products be stored and handled?

Proper storage and handling of oven cleaning products ensures both safety and product effectiveness whilst preventing deterioration that could compromise performance or create hazards. Store products in cool, dry conditions away from direct sunlight and heat sources that could affect chemical stability or container integrity. Maintain storage temperatures within manufacturer recommendations, typically between 5-35°C, to prevent freezing damage or excessive heat that could cause product degradation. Ensure storage areas are well-ventilated and segregated from food items, with appropriate secondary containment for potential spills or leaks. Keep products in original containers with intact labelling that provides essential safety information and usage instructions. Implement first-in-first-out inventory rotation to prevent products from exceeding recommended shelf life, which varies by formulation but typically ranges from 2-5 years for quality commercial products. Provide appropriate personal protective equipment including gloves, eye protection, and respiratory protection where recommended by safety data sheets. Establish procedures for handling spills, accidental exposure, and emergency response that align with product safety information. Train staff on proper handling procedures, hazard recognition, and first aid measures appropriate for the products being used. Consider environmental factors such as humidity, temperature fluctuations, and potential contamination sources that could affect product quality or safety. Secure storage prevents unauthorised access whilst maintaining convenient availability for authorised personnel, and proper documentation helps track usage patterns and identify when reordering is necessary to prevent supply interruptions.